Minerals known to be scarce, essential or critical are directly related to country development and are, therefore, classified as strategic reserves [1]. The wide variety of existing ores allows the production of seventy-two types of strategic minerals, twenty-six of which are of metallic origin. Steel, a metallic alloy obtained one (or more) of those strategic minerals, is a fundamental material for the economy of several countries around the world [2]. Iron ore is the main raw material for steel production, which, in turn, is used in several productive sectors, in particular, in civil construction, applied to foundations, structures and facades. Steel construction currently represents about 60% of the building sector universe. According to [3], the civil construction sector consumed during the first decade of the 21st century more than 1.8 million tons of steel per year, exclusively for the construction of metal structures.

The use of steel undoubtedly represents an evolution for society. However, the conventional technologies used for its manufacture result in extreme environmental effects. As a commodity, steel processing predisposes significant consumption of mineral resources. In addition, this production cycle is known for being energy-intensive, as well as for the generation of high amounts of atmospheric emissions, in the form of Greenhouse Gases (GHG) and acid rain, and particulate material, i.e., water, and the soil, in these cases, in the form of sludge and slag [4].

The technical literature comprises several publications that describe environmental impacts associated with steel manufacture, as well as practices and conducts that have been implemented by the sector to reduce these effects. However, most studies were restricted to one stage (or equipment) of the transformation chain, such as the extraction of natural resources (or blast furnaces), therefore adopting a gate-to-gate approach [4]. Oyama et al. [5] developed and implemented the hydrogen fuel injection technology by the JFE Steel Corporation, during 2009, in order to improve sintering quality without increasing carbon dioxide equivalent (CO2eq) and particulate material emissions. As a result of this development, the authors identified a 60,000 t/year reduction in carbon dioxide (CO2) emissions. This approach presents the loss of the interrelationships of the analyzed stage as a limitation, with others placed upstream and downstream of the production chain. For a systemic analysis, such as that concerning production chains, this can lead to a skewed performance view.

In order to solve a problem concerning the excess disposal of solid waste, Salmi and Wierink [6] carried out a case study on the effects of using sludge and powders from a steel mill, converting them into raw materials for the iron and zinc industry in rotary kilns in the Gulf of Bothnia. In steel production, the impact of the recovery of the generated tailings results in a 32 kg CO2eq/t decrease of crude steel, while an increase in the carbon emission equivalent of the conversion industry was observed. That study did not carry out a systemic environmental analysis, which would have been able to verify the scope of this alternative for reducing global impacts, i.e., if the reuse achieved concomitant impact reductions for the steel industry and for the iron and zinc industry. With the same intention, Nowacki [7] investigated the environmental impact of steel industry waste and the possibility of recycling iron through the process of reducing iron oxides. This technological proposal was proven viable, since reduction by using carbon monoxide (CO) between 850 and 1050 °C allows for over 90% of residue metallization.

Still concerning solid waste from the steel industry, Branca et al. (2020), elaborated a study on the most recent results concerning the reuse and recycling of by-products of European steel companies and cooperation actions with other carbon source activities, with the aim of obtaining a global perspective of the state of the art in this regard. That study indicated the need for improvements in the obtained by-products, so that reuse or recycling rates are improved. Thus, it was concluded that the development of new technologies is paramount, resulting in a cleaner industrial process [8] .

Solutions for reducing energy consumption in the mining stage and steel production process were also investigated [9]. In this case, the authors concluded that, although 70% of the energy spent in mining is in the ore comminution stage, this expenditure is worse in steel production. With a 50% increase in energy efficiency in comminution, the environmental impact on production becomes seven-fold lower. With the use of charcoal as biomass and dry slag granulation, the authors indicate that it will be possible to save 30,000 PJ/year in 2030. Thus, energy savings due to process modification are observed (Cleaner Production). However, the sector seems to understand that there is an immediate correlation between reduced energy consumption and reduced associated environmental impacts, which is not always true and, therefore, must be explored systemically, which was not carried out in the aforementioned study.

The Life Cycle Assessment (LCA) technique plays an important role in evaluations carried out on the steel industry concerning Biosphere-Technosphere interactions, as verified in the aforementioned studies. However, the systemic character that this analysis predisposes is depreciated, and many studies do not take advantage of the fullness of this approach. According to Yellishetty et al. [7] this occurs because the LCA models are forced to deal, not always successfully, with some scientific anomalies in its application to the mineral sector, as the quantifying the depletion of abiotic resources. Seeking to mitigate such an effects, Vadenbo et al. developed a tool that combines process models with LCA databases to evaluate the use of alternative resources in the steel industry, considering various arrangement configurations [8].

GHG emissions are a constant concern for the steel industry. One way to reduce this effect is to replace mineral coal with renewable biomass. Investigating the use of charcoal in this function, Vadenbo et al concluded that this solution may indeed decrease Global Warming impacts, but to do so, certain procedural aspects (i.e. the pyrolysis velocity and the composition of the biomass) need to be controlled. Following on the same track Norgate and Jahanshahi noted that the biomass from plantation wood, as well as biomass residues (e.g. sawdust), can also lead to reduce GHG emissions compared to coal [9].

Recent studies [9] showed that GHG emissions can be dampened by integrating the energy flows in existing steel plants and mitigating CO2 releases by installing carbon capture and storage technologies. Together these actions can decrease specific emissions by 40 – 50%. More severe changes are also possible through the transmission of carbon-based metallurgy (coal, coke, oil, natural gas) to produce carbon-free iron, combining H2 reduction and fusion with low-carbon electricity. Another way to mitigate GHG losses is the use of recycled steel (from 30% to 50%) in the process. An study on the production of electric vehicles [9] reinforced the benefits in terms of Global Warming Potential (GWP) provided by the use of H2 in iron reduction during steel processing. According to the authors, the total GWP of the process would be 17% less than that achieved by current technology. Chisalita et al. [9] also investigated the environmental effects of CCS on steel production. Comparing two post-combustion CO2 capture technologies the authors concluded that such kind of integration can decreases the GWP from 48 to 76%. However, Chisalita et al. warn that the use of CCS can rise impacts in other categories, since this technologies leads to reduce process efficiency.

Logically, the application of LCA is not restricted to determining GWP impacts of steel processing. This is so true that Ma et al. [9] performed an LCA and grey and blue water footprint analyses in order to supporting decisions in the Chinese steel sector. The study identified Metal Depletion, Global Warming, Ecotoxicity and Respiratory diseases as sources of environmental degeneration caused by crude steel production. Water stress due to the discharge of process effluents varied at the provincial level, indicating that water footprint should consider regional aspects in the quantity and quality of resources. Liu et al. (2020) [9] analyzed the main iron and steel producing countries for assessing the environmental impacts and the related economic value within countries, as well as between them (trade relations). The authors maintain that countries benefited from the import of "pollution-free" materials must proportionally share the responsibility for impacts caused by activities that take place in their trading partner countries. Olmez et al. [9] evaluated the environmental profile of the steel industry in Turkey.

The comparison of impacts for different final products revealed that hot rolled coil causes the highest total environmental impact followed by hot rolled wire rod, billet and slab. The hot rolling of the molten products greatly influences the results, representing until 24% of the total impacts of those materials. Taking a correlated approach Bieda et al. [9] elaborated the life cycle inventory (LCI) to a continuous casting of steel process located in Poland. The study generated a database regarding to the production of steel slabs for the year 2015.

The European steel industry was addressed from the perspective of integrating LCA with system dynamics (SD) within the scope of circular economy and industrial ecology. Pinto et al. [9] explored if the integration could reproduce results generated separately by LCA and SD, and support decision- and policy-making on the biophysical aspects of long-term materials sourcing. After careful examination Pinto et al concluded that both objectives are feasible. Finally, a social life cycle assessment was developed in India to understand the effect of steel industry operations on society [18]. The confrontation of stakeholders' expectations with the management revealed that economic prosperity, access to clean water, education, healthcare facilities, workplace safety and infrastructure and are key aspects which need to be improved.

Although the environmental issue has been a recurring target of interest to the steel sector, a bibliographic survey carried out on the technical literature dealing with the topic did not return any analyses identifying environmental impacts associated with the steel production cycle to propose alternatives that reverse improvements of its performance within this application domain. This study aims to partially fill this gap by verifying the environmental and energy feasibility of actions to be implemented in the steel production chain in Brazil. One of the ways to improve the relationship between the steel industry and the environment is to carry out a systemic and integrated analysis of the entire life cycle of steel, in order to identify opportunities for mitigating its impacts. This type of analysis can be provided by LCA. The domestic steel sector must rely on a study of this size to make its management more economically profitable. Once the environmental performance improves, the process efficiency also rises, reducing resource consumption and emissions and, hence, increasing revenue.

The method established to perform this study encompasses the steps of: (i) conception of a dynamic model, based on a primary data survey from a large industry in the Brazilian steel sector and secondary data collection from the technical literature and databases; (ii) application of the LCA technique, performing a systemic diagnosis of the environmental impacts associated with this process; (iii) selection and sizing of alternative solutions for the identified problems; and (iv) investigation of the effectiveness of the proposed solutions, in terms of environmental and energy performance improvements.

Life Cycle m odelling

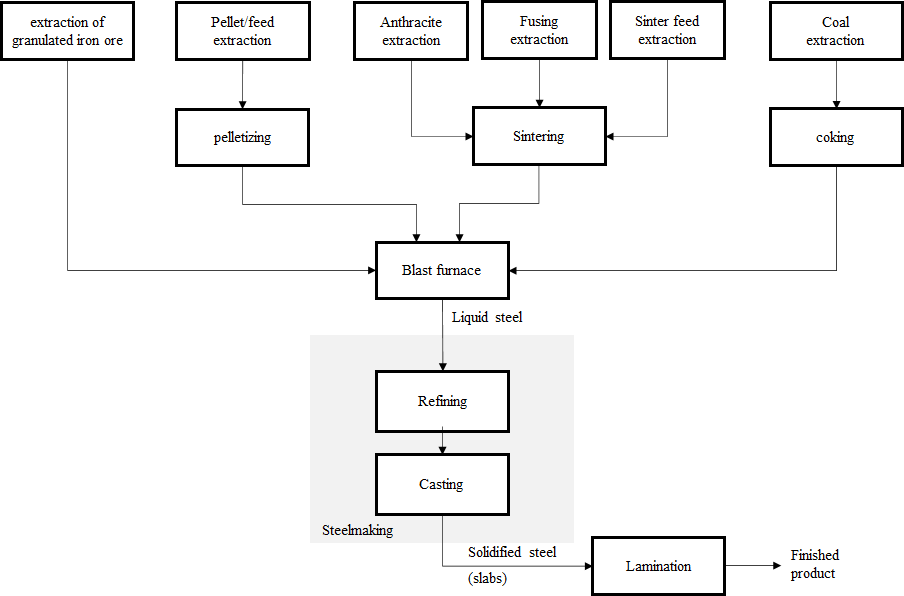

According to a report by the World Steel Association (WSA) about 70% of the world's steel production occurs through the Blast Furnace/Converter route [10]. The arrangement presented in Figure 1 indicates that the process basically comprises the stages of resource extraction, iron ore agglomeration (sintering and pelletizing), fuel production and iron reducing agent (coke oven), oxide iron reduction in pig iron (blast furnace), refining pig iron to obtain steel and solidify it into slabs (steelmaking) and mechanical conformation (lamination). A brief description of each stage will follow.

Stages of the steel production process

Sintering/Pelletizing. In the sintering process, the sinter feed (iron ore with an average grain size of 1.0 mm) is agglomerated, generating a prepared load rich in iron, the sinter product. The same occurs in pellets, where the pellet feed (with average grain size below 0.10 mm) is also agglomerated to originate the pellet [11]. Of all the energy required to move the combustion front, 85% comes from the fuel (fine coke) and the remainder from the ignition (burner)) [12]. Sintering is able to recycle by-products and powders produced in the steel industry itself. However, this process predisposes high energy consumption, mainly from non-renewable sources, such as coke and anthracite [11]. The consumption of solid fuel in sintering plants varies from 45 – 60 kg/t produced sinter. In pelletizing, the burning of “blast furnace pellets” is performed by combustion of fuel external to the mixture, burning oils, natural gas and other fuels that generate the hot gas responsible for burning raw pellets [12]. In general, the process also results in negative environmental effects, due to GHG and particulate matter emissions [13]. Pellet production technology is not yet consolidated in all steel-producing plants and this asset is generally purchased from external suppliers.

Coking. The coal mixture is heated in furnaces under reducing atmosphere in order to release volatile compounds. The pyrolysis of coal develops from the walls to the centre of the equipment. During this transformation, the coal goes through softening, contraction and, subsequently, solidification stages. Two kind of products use to be generated from these reaction sequence: the coke itself, obtained in a solid state, and a gaseous fraction comprising coke oven gas (COG) and carbo-chemical products (benzene, naphthalene, tar, among others) [14]. The coke leaves the oven at ~1300 °C and must be cooled to fulfil its process functions. The product goes into extinction (or erasure) towers. The most common quenching process is wet wiping, where the incandescent coke comes in direct contact with water.

Approximately 95% of the water evaporates, given the high temperature of the coke, and the rest is incorporated into the product. The coking stage stands out due to its high energy consumption and GHG emissions. Around 50% of the energy consumed in an integrated steelmaking process is represented by this step [15].

Blast furnaces. Blast furnaces are the main steel industry equipment, and their objective is the reduction of iron oxide through carbon from coke. Ferrous loads (metallurgical sinter, granular ore and pellets) and coke are fed on top of the reactor in order to form alternating material layers. During the coke combustion process, carbon monoxide (CO) is released at temperatures up to 2200 °C and percolates the reaction mass in a counter current. CO is responsible for reducing iron oxide, which occurs when the ore load reaches 1100 °C – 1200 °C. The reduced iron (in a liquid state) drips onto the solid and not yet reduced mass.

On the way to the crucible, it incorporates impurities such as carbon and phosphorus. Under these conditions, the liquid pig iron leaves the furnace with an approximate composition of 95% total Fe [16]. During this stage, impurities are released comprising the slag, consisting mainly of silica. The material is formed at ~ 1400 °C in a liquid phase [16]. In addition to the slag, the unit also generates blast furnace gas (BFG) which, after being emanated, undergoes a washing step, originating the so-called blast furnace sludge [17]. When it is not recycled internally in sintering plants, the sludge is destined for industries in the ceramic segment (acting as a carbon and, therefore, energy supplier), or is disposed of in landfills. In addition to release GHG and particulate into the atmosphere this stage is energy intensive [17]. The most recently designed blast furnaces are equipped with top turbines capable of producing electrical energy from the pressure exerted by this gas when leaving the reactor, reducing the process dependence on external sources [18].

Steelmaking and Laminations. This activity can be performed through the operation of the following equipment: Converter (BOF), Electric Arc Furnace (EAF) or Open Hearth Furnace (OHF). The main processes developed in this stage are applied to refine pig iron. About 70% of steel production is carried out through the Blast Furnaces/Converters route. Another 29% use BOF and 1.0%, OHF [19]. In this technology, oxygen (O2) is injected through a refrigerated lance that causes the release of a high amount of heat. As the oxidation occurs under controlled conditions, CO is obtained, which is responsible for the full agitation of the material. The energy generation during the process is restricted to oxygen administration. Therefore, no other thermal source addition is required. The injection stops when the carbon content in steel reaches a limit up to 2.0% [15]. The liquid steel can be taken to secondary refining (more specific quality adjustments), or go directly to the casting, where slabs, billets or blocks will be produced. The steelmaking process generates steelmaking gas (LDG), whose washing, carried out to meet legal pollution control requirements, results in sludge production, which can also be recycled internally or destined for sanitary landfills. The plates can also go to lamination, where they are submitted to mechanical conformation to become coils or sheets. This operation can occur under cold (cold rolling) or hot (hot rolling) conditions [15].

Environmental Aspects Associated with Steel Processing. Air quality is a parameter of great importance in the steel industry and must be mapped and controlled. Its quality is fairly conditioned by the (high) energy and raw material consumption in the stage. Thus, emissions of CO2 and acid rain gases, (i.e. nitrogen and sulphur oxides: NOx and SOx), are expected. According to WAS the CO2 corresponds to 93% of all GHG emissions from the steel industry [20]. The process is responsible for emitting around 1.7 t CO2eq in the form of GHG for each ton of steel produced and this sector emits about 6.7% of all global CO2 from industries [21]. The steel production comprises high consumption of brackish and fresh water for cooling purposes. When possible, sea water is preferred for cooling areas, due to its high availability and low cost. In addition, the quality of the cooling water is not significantly altered, with only a slight temperature gain, so it can be returned to the sea. Other water purposes in the steelmaking process refer to the stripping and gas washing processes. More recently, the sector has become able to reuse and recycle a large amount of the captured water through available technologies [22]. Impacts have been assessed both concerning generation and transport to verify environmental loads associated with electric energy throughout the steel life cycle [23].

Steel production presents high energy consumption and is responsible for expressive generation of GHG. The manufacture of steel itself, and the productions of coke and sinter are the main sources of these emissions [24]. The utilization of alternative fuels as charcoal, has been recommended to addressing such a problems and their adverse effects on the environment. However, the decision to use renewable fuels in the process must take into account the impacts this action will have on other categories such as Land Use, Primary energy demand, and Aquatic and Terrestrial Ecotoxicity [22].

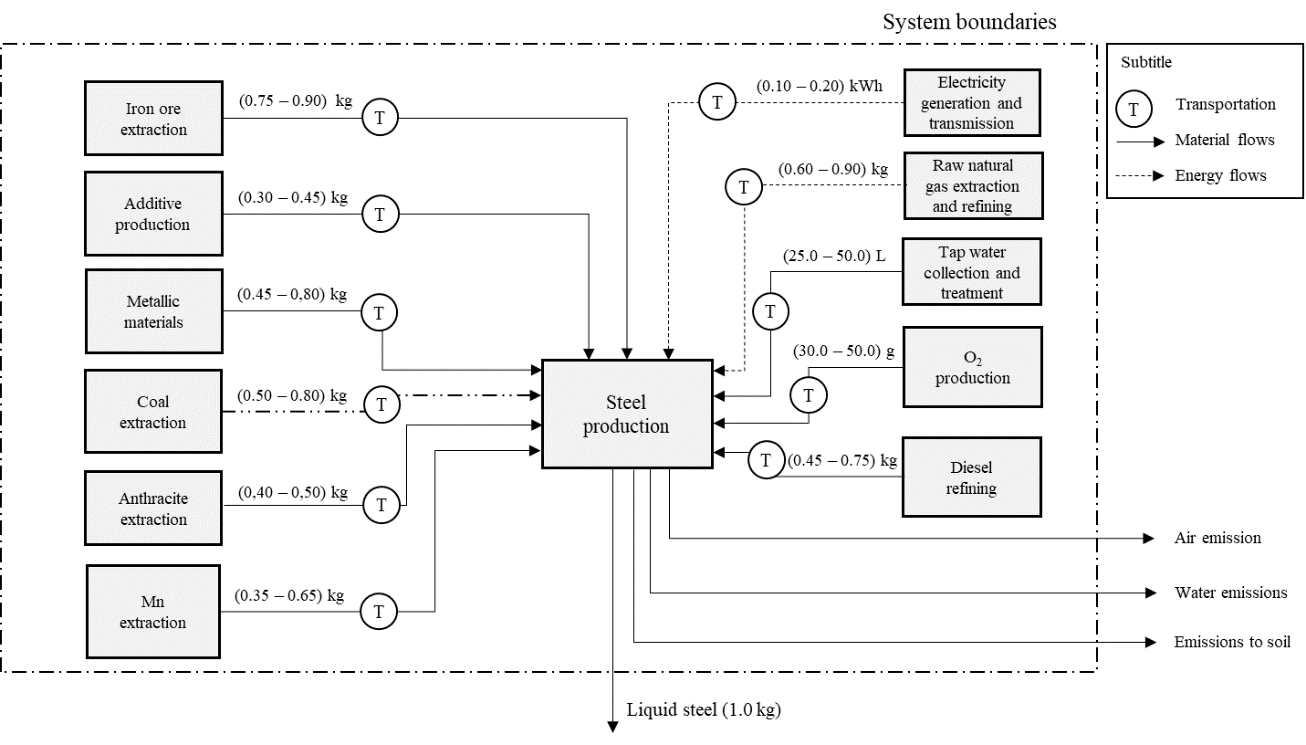

LCA: Scope definition. The environmental diagnosis of steel production in Brazil was conducted according to the guidelines from ISO 14044 [25], by attributional LCA, under a "cradle to gate" approach and for a Reference Flow of 1.0 kg of liquid steel.

Primary data collected in loco along a real production process expressed consumption and emissions associated with liquid steel manufacturing. On the other hand, mass and energy currents associated to the extraction and transportation stages of raw materials (i.e. iron ore, coal/anthracite, manganese, additives and other metallic inputs added to the process) were represented by secondary data collected in scientific publications, technical documents, and databases supporting correlated LCA studies. In cases of these nature, treatment and validation procedures were applied in order to harmonize the consistency of such parameters with that of the primary data. This was also performed for the process utilities (water, electricity and natural gas), diesel oil and transportation. With regard to the data Temporal Coverage, the primaries originated from successive surveys carried out in a plant, throughout the twelve months of 2018. The Geographical Coverage took into account an unit installed in the state of São Paulo and for inputs obtained via imports, their respective production sites were included. The Technological Coverage follows the description previously presented in Life Cycle Modelling section that is also depicted in Figure 2. Cut-off criteria have been applied for modelling the product system. From that, flows whose cumulative contributions in terms of mass and energy are lesser than 1.0% have been disregarded. However, if these amounts proved to be environmentally relevant for the process, they were reintegrated into the model as suggested in ISO 14044 [25].

Two multifunctional situations have been identified in the product system. The first, was defined in the steel manufacturing and occurs among liquid steel, blast furnace Slag, and steel slag. The case was treated by allocation using mass amount as criteria. The second multifunctionality occurs in the oil refining involving Green Petroleum Coke (GPC) and diesel. The problem was also solved by allocation but the energy content was applied as criteria. As a result, GPC and diesel received respectively 6.0 and 22% of the previous environmental loads associated with this branch of the process.

Product system of liquid steel production

The life cycle impact assessment stage of LCA expresses the numerical data from the inventory into environmentally relevant results (i.e. impacts). For the case of the Brazilian liquid steel production this analysis was carried out in two levels. In the first, aimed at investigating effects in terms of energy resource consumption, the Cumulative Energy Demand (CED) v 1.09 method [24] was applied to quantify the Primary Energy Demand (PED) of the scheme. The impact categories considered in this approach were: Non-Renewable Fossils (NRF), Non-Renewable Nuclear (NRN), Non-Renewable Biomass (NRB), Renewable Water (RW), Renewable Biomass (RB) and energy due to natural effects (wind, sun and geothermal) (RWSG). At the second level, which quantifies effects in terms of emissions, the ReCiPe Midpoint (H) v1.12 method [26] was used to assess the impacts of Climate Change (CC), Eutrophication (EUT), Ozone Formation (POF), Terrestrial Acidification (TA), and Water and Metal Depletion (WD and MD).

This section presents and discusses the results that describe the environmental and energy performance of the technology currently practiced in Brazil for the production of liquid steel. Moreover, it describes the actions proposed for potential improvement of those results, as well as, evaluates their feasibility for the same dimensions, taking into account the local conditions available for their implementation.

For Primary Energy Demand (PED) values associated with the production of 1.0 kg liquid steel are as follows: 94% for the NRF impact category, representing a significant share of the total result of energy demand. The contributions derived from the depletion of coal, oil and natural gas, which represent 54%, 29% and 3.4% respectively of the 26.1 MJ/kg of liquid steel in the form of NRF, are noteworthy.

In terms of participation by the process stage, the main contributions for NRF are related to mineral coal extraction (58%) followed by the oil refining for CVP production and transport (29%) and, although lower, the anthracite mining (5.1%).

Mineral coal represents the main source of PED. Its participation (15.0 MJ/kg steel) originates from a consumption of 540 g/kg, divided between matter supplies, in the form of carbon (C), and process energy. According to the Brazilian Energy Balance [27], the country produced the equivalent of 2.0 Mtep of mineral coal in 2018, corresponding to only 16% of its domestic needs for the period. In addition, Brazilian mineral coal does not meet the quality requirements need by the process, because it is rich in ash and sulphur [28]. The only carbonaceous material used from Brazil is CVP. PED holdings associated with its production occur in the form of oil refining (7.39 MJ/kg steel). The production and transport of this raw material contributed with 7.44 MJ/kg, due to its consumption (140 g/kg steel) in the process. Anthracite also has a small participation in PED (1.38 MJ/kg steel), also because of its extraction and transportation, related to a input of 48.6 g/kg steel which aims to exclusively supply part of the energy demand in the process.

Some of the assets consumed by the Brazilian steel industry are obtained by imports. This occurs particularly with the mineral coal which is supplied by mines from Australia, Colombia, Russia and the United States. Although transoceanic displacements from these centres to Brazil occur for significant lengths (Australia: 14636 and 14696 km; Colombia: 7604 km; Russia: 12412 km; and United States: 9466 km) fuel consumption related to such operations (which would also result in oil depletion) were discreet, totalling 1.06 MJ/kg steel.

Table 1 describes the results of applying the ReCiPe - midpoint Method (H) for the purpose of quantifying impacts resulting from emissions originating from the production of 1.0 kg liquid steel. The result obtained in terms of CC (1.53 kg CO2eq/kg steel) shows adherence to the Association World Steel Corporation and Instituto Aço Brasil reported when compared to the same conditions and degree of progress of the process (up to the limit of obtaining liquid steel). The main CC precursors are CO2 and methane (CH4) emissions, both of fossil origin, whose contributions represent 96% and 4.0% of the total performance for the category, respectively.

Fossil CO2 emissions were diagnosed in multiple operations throughout the liquid steel production chain. Among these, the following are noteworthy: the manufacture of the steel itself, transport, oil and natural gas refining and electric energy generation. Steel manufacturing contributed with 1.56 kg CO2/kg liquid steel (87% of the system's total CO2 emissions). This performance is justified by the fact that almost the entire process uses thermal energy obtained by combustion of natural gas, coal and oil products, which result in CO2 as material waste. Transport activities account for a total of 8.4% of CO2 losses. Of these, exactly 59.5 g CO2/kg steel are emitted in transoceanic displacements that occur for mineral coal and anthracite, imported from Ukraine, and domestic transport of manganese; 44.7 g/kg are emitted during rail transport (also for coal and anthracite, as well as iron ore, metal shavings and manganese); and 15.7 g/kg during road transport (for iron ore, limestone, lime, dolomite, shavings and CVP).

Environmental Impact profile of the production of 1.0 kg (liquid) steel

|

Impact category |

Unit |

Total |

|

CC |

kg CO2eq |

1.53 |

|

TA |

g SO2eq |

3.69 |

|

EUT |

g Peq |

1.28 |

|

HT |

kg 1,4-DBeq |

0.73 |

|

POF |

g NMVOC |

3.79 |

|

WD |

L |

406 |

|

MD |

kg Feeq |

2.90 |

CO2 losses of 19.6 g/kg occur in oil refineries used for CVP production. Finally, the national electricity matrix in 2019 contributed with 17% from fossil sources, of which 55% originate from natural gas, 17%: oil derivatives, and 14%: coal [29]. For the purpose of generating thermoelectric energy, these sources together contributed with 31.8 g CO2/kg steel to the process. CH4 emissions originate mainly from mining and transporting coal (1.91 g/kg steel). Of these, 60% (1.15 g/kg) refer to coal production and transport in the United States and another 15% (290 mg/kg) are related to CVP production and transport. Anthracite mining and transportation emitted to 460 mg/kg of the total CH4 emitted.

The environmental impacts related to TA were mostly caused by SOx (53%) and NOx (39%) emissions. SOx losses are linked to the burning of diesel oil for transoceanic and rail transport (resulting in contributions of, respectively, 940 and 160 mg/kg), in addition to oil refining for CVP production (340gm/kg). In part, NOx emissions follow the same pattern as sulphur oxides, concentrated in transoceanic (990 mg/kg) and rail transport (310 mg/kg) also due to diesel oil burning. Mining contributions should be added to this amount due to dynamite detonation (550 mg/kg) and machine activation (120 mg/kg).

As for EUT, environmental effects are entirely due to phosphate (PO43-) losses to water. These originate from coal mining tailings leaching (3.45 g PO43-/kg steel) and disposal of tailings from the steel processing itself (280 mg/kg) even in situations where the final disposal occurs in controlled landfills. The average phosphorus content of the world coal reserves is on the order 500 ppm [30]. According to those authors, the P associated with coal structure originates from phosphoproteins from the original peat, volcanic debris, shells, and even faecal matter deposits, so the coal used in coke synthesis must meet several quality requirements [31] which indicates the maintenance of low levels of P ( 100 ppm). The processing of raw mineral coal is, therefore, inherent to the steel segment, and the tailings landfill disposal originated in this process is a recurring practice among large raw material producers [32].

The adverse impacts caused by the process in terms of HT stem from arsenic (4.5 mg /kg steel), selenium (3.40 mg /kg) and manganese (840 mg /kg) water losses. All of these emissions also originate from the coal mining process.

The most active POF precursors are NOx and volatile organic compounds emissions other than methane (NMVOC) into the atmosphere, at 68% and 23% of total impacts for the category, respectively. NMVOC losses (875 mg/kg steel) come from oil refining for the production of CVP, whose contribution is of 570 mg/kg. In addition, contributions were also made to the transport of raw materials in general, which together contributed with 130 mg/kg (comprising 54% for transoceanic transport, 27% for rail transport and 19% for transport road).

Steel manufacture generates a specific water consumption of 36.5 L/kg steel, that is, 90% of the total impacts generated by the system as WD. Water consumption is a highly variable parameter among the companies that make up the Brazilian steel sector. This performance is conditioned by several parameters, including technological route, existing production units and, resource management strategies [33]. However, according to IaB statistics, this figure for the year 2017 was, on average, of 42.6 L/kg for plants integrated with coke [34], the specific case of the process object of this study. On the other hand, it must be argued that 82% of this total comes from brackish water captured in the ocean used for cooling equipment by indirect contact. When discounting this portion for both situations, it is noted that the results in terms of WD obtained for the assessed model (5.83 L/kg) are in line with the average of national plants (6.96 L/kg) in terms of specific consumption of freshwater. In general, 75% of water use in the steelmaking process is intended for heat exchanges, 13% is used to control air pollution, and the remaining 12% is used for conditioning materials [35]. The coke oven results in high water consumption, due to quenching, when wet. In the auxiliary units, the boilers that make up the energy cogeneration cycle (thermal and electrical) of the plants appear as the main demand due to their emission control system[36]. Finally, it should be noted that the average water recirculation rate in the Brazilian steel production segment is of 96% [34].

Metal depletion (MD) corresponded to 2.9 kg Feeq/kg liquid steel. Of this total, 76% derives from manganese (Mn) extraction and the remainder, from Fe ore mining, which, in this case, includes the mining of sinter feeds, granular ores and pellets. Although the individual consumption of Fe ore (1.47 kg/kg steel) is higher than that of Mn (46.9 g/kg), the predominance of the latter's contribution is explained by a combination of two factors. The first is linked to the composition of iron ore. For the purpose of these estimates, the Fe content in the ore is of 49%, a typical value for Brazilian deposits [23, 38]. Therefore, the consumption of this mineral resource by the process is of 690 g Fe/kg steel. The Mn content in the ore was established at 6.3%, thus projecting a depletion of 28.7 g/kg steel.

The second factor capable of explaining Mn supremacy is linked to the Life Cycle Impact Assessment model that was selected to quantify the impacts associated MD. The approach proposed by Goedkoop et al. [37] considered Fe the reference substance for the category, attributing an impact factor IF = 1.00. Mn, whose availability throughout the globe is lower than that of its metallic counterpart, received, IF = 76.6. Therefore, when expressing the participation of Fe and Mn for MD using that model, 690 g Fe eq/kg steel for Fe and 2.20 kg Fe eq/kg for Mn, respectively, are obtained. It should be noted that in this modelling, manganese ore was considered as a source of Mn, contrary to the practice of the steel industry, which considers it as a source of iron, even though containing low Fe content, and which is also rich in an important accessory mineral to the process. Based on this convention, the material chain referring to 'manganese ore' should be incorporated into that referred to in the ICV as 'iron ore', a condition that could change not only the distribution of components that impact the MD category, but also their total results.

The initial analyses indicated that the main sources of environmental impacts associated to the production of liquid steel result from the consumption of diesel oil in the process itself, from coal mining activities and also from the transportation of raw materials and inputs. Diesel consumption was the majority in terms of PED, in the form of NRF depletion. In addition, it was also responsible for the most significant environmental impacts in terms of CC, TA and POF. Coal mining was even more eclectic in terms of participation in the evaluated impact profiles concerning contributions in terms of CC, TA, EUT and TH.

Finally, transport actions appear motivated in part by the internal unavailability of process inputs (i.e. mineral coal and anthracite) and the distancing of the plant considered for the purpose of this analysis of centres supplying raw materials (e.g., Fe ore) and process additives (Mn, limestone, and dolomite). Although the values quantified both in terms of PED, and due to environmental emissions may seem discrete, one must take into account the significant volume of steel produced in Brazil every year. In view of this condition, it becomes imperative that actions to improve the environmental performance of this production cycle be observed at a systemic level.

The initial diagnosis revealed that the main stages responsible for the impacts inherent to the process are: (i) its overall electricity consumption from the Brazilian grid, (ii) steel manufacture, and (iii) the water collection and transport. On this basis, it was possible to propose solutions for improving the environmental performance of the scheme, namely: S1: use of steelmaking gas to produce electricity; S2: installation of coke dry quenching (CDQ) technology; and S3: replacement of the manganese ore supply. Although S3 does not act directly on the main impact foci identified by the LCA, this action was a request from the company that provided the primary data used in the analysis.

In S1, the steelmaking gas, which is originally rejected from the process, can be reused in a thermoelectric plant a source of energy generation. The flow has sufficient quantity and energy content to meet this function, although certain adjustments in the process scheme are necessary to make it feasible. For S2 the implantation of CDQ reduces the process water intake, in addition to extracting heat from the coke by direct contact with an inert gas. Carrying the sensitive energy surplus from the coke, the gas goes to a boiler in order to generate steam, which feeds a turbo generator. Therefore, the use of CDQ also reduces external energy inputs on the process. After releasing heat to the water, the gas leaves the boiler and returns to the quenching chamber, remaining in a closed circuit. The replacement of manganese ore supply requested by the company (S3) produces a sinter with 7.1% less SiO2 than the original scenario, in addition to increasing the iron content. With the establishment of improvement scenarios, another LCA was carried out to verify the effectiveness of the proposed solutions. The technique was applied once again under an approach from cradle to gate for producing 1.0 kg of liquid steel.

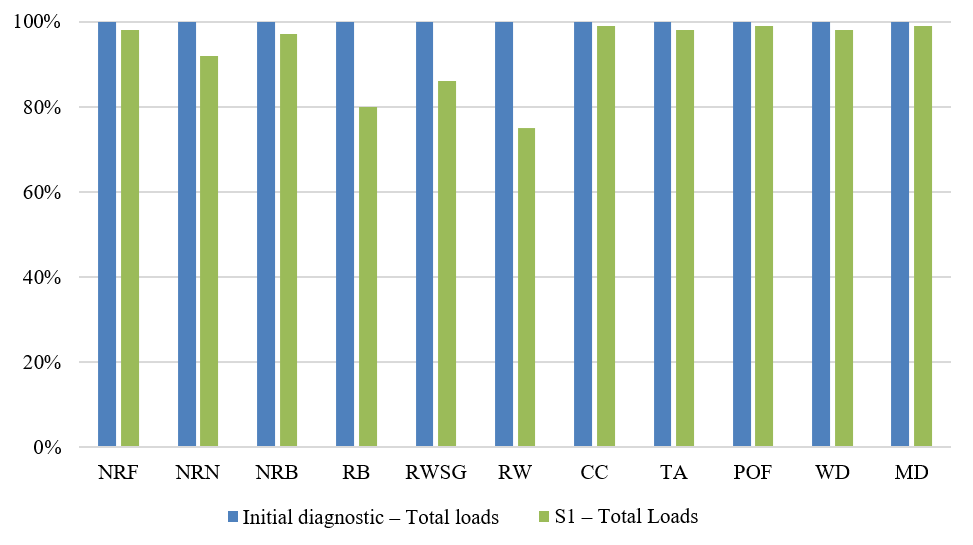

Concerning Primary Energy Demand the LCA carried out considering S1 indicated an slight improvement in environmental yield in the production of liquid steel compared with the initial diagnosis. As depicted in Figure 3, the most relevant gains occurred for the subcategories of RB, RWSG and RW. However, the overall result is not significant as those sub-categories of impact had discrete contributions to the former performance of the arrangement in terms of PED.

Comparison of the environmental profiles of liquid steel production for the Initial Diagnosis vs S1 - Total loads

Although the 2018 Brazilian grid was more than 83% made up of renewable sources [25], the improvement in PED performance provided by S1 does not come as a surprise. This is justified by two factors: (i) despite the origin of electricity, liquid steel processing remains energy intensive; and (ii) as steelmaking gas is originally process tailings, its use for electricity generation becomes a revaluation. Thus, the specific environmental load of this flow is now computed as null for modelling purposes.

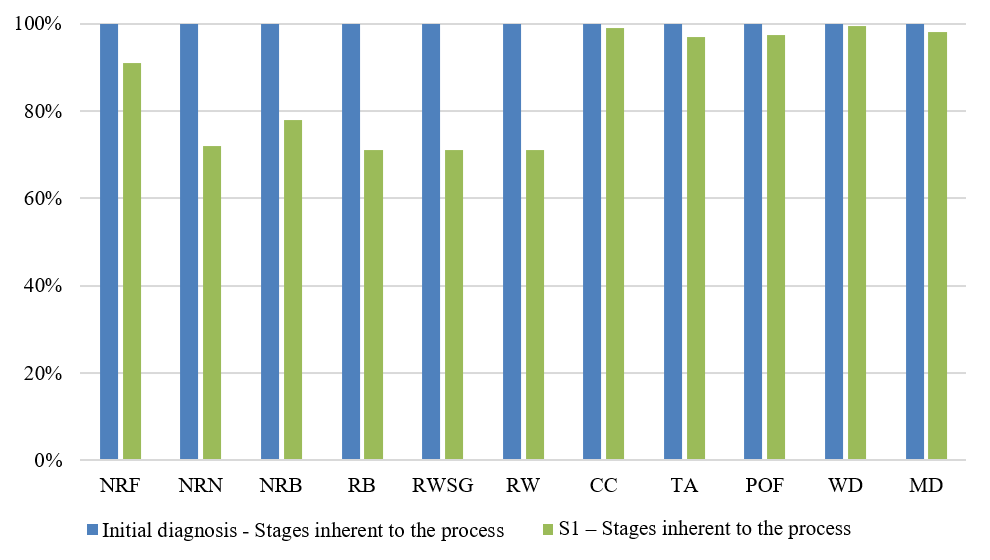

Comparison of the environmental profiles of liquid steel production for the Initial Diagnosis vs S1 - Stages inherent to the process

In order to address the issue from a different perspective, an alternative analysis was performed considering only the steps inherent to the processing of liquid steel for S1. The obtained totals were also compared to those of the initial diagnosis for similar conditions (Figure 4). Within this scope, an expressive reduction in terms of PED were observed, as the contributions of all the impact subcategories decreased. As occurred for the product system as a whole, the power generation via steelmaking gas recovery was less intense in terms of NRF (8.0%) than for RWSG, RB and RW, which reductions ranged between 12 to 24%. On the other hand, even if cushioned, the benefits obtained from the NRF were decisive for the improvement of PED introduced by S1.

PED values displayed an accumulated reduction of 17%, with the implementation of S1 for stages inherent to the process. The NRF category comprises a 59% share of energy demand, compared to 94% in the base scenario. However, electricity consumption was the most expressive result, with a reduction of ~ 45% in the dependence on the Brazilian Grid (from 932 to 516 kJ/kg steel, in S1).

Also as observed in Figure 4, the impact profiles of CC, TA, POF, WD and MD, did not result in significant changes with the implementation of S1, even when referring to the inherent processing loads. Regarding Climate Changes there was a discrete reduction (0.5%) of impacts compared to the initial diagnostic performance. In absolute terms, the retraction obtained with the revaluation of steelmaking gas was 4.37 g CO2eq/kg steel. The slight effectiveness of the changes introduced by S1 on CC is because these measures do not act on steel manufacture emissions, which account for 98% of the contributions to the category.

For TA there is a 3.5% reduction in S1 performance over the initial diagnosis. The losses of SOx and NOx continue to contribute the largest share of this category: 53% and 36% respectively. As in the case of CC, S1 had no influence on the main focuses of TA impact generation, the steel manufacturing. This stage accumulates the almost full SOx emissions of the system, plus 86 % of its NOx emissions. The latter are supplemented by emissions from natural gas (2.9%), coal (2.1%), heavy oil (1.7%) and sugarcane bagasse (0.9%) derived from the thermoelectricity fraction of the Brazilian grid. The reductions in airborne losses of CO2, N2O, SOx and NOx are largely due to the fact that the national matrix for 2018 includes 17% from fossil sources, of which 51% refers to natural gas, 22% to coal, and the remaining 11% to oil and derivatives [25]. The effects of S1 on POF are justified by the same arguments that described its action on AT since both categories have in SOx and NOx their main precursors. Finally, S1 has not recorded any notable changes on WD and MD.

Some complementarily assumptions were considered for modelling S2, in addition to those already described: (i) coke fed to the quenching chamber at 1250 °C and emanating from it at 180 °C; (ii) the gas used to quench the admitted coke behaves as an ideal fluid; (iii) the water or working fluid emanating from the turbine is considered in liquid-vapor equilibrium at 1.0 bar and 99 °C, and title x = 90%; (iv) the energy conversion efficiencies of the boiler and turbine must be, respectively, ɛc = 95% and ɛt = 82%.

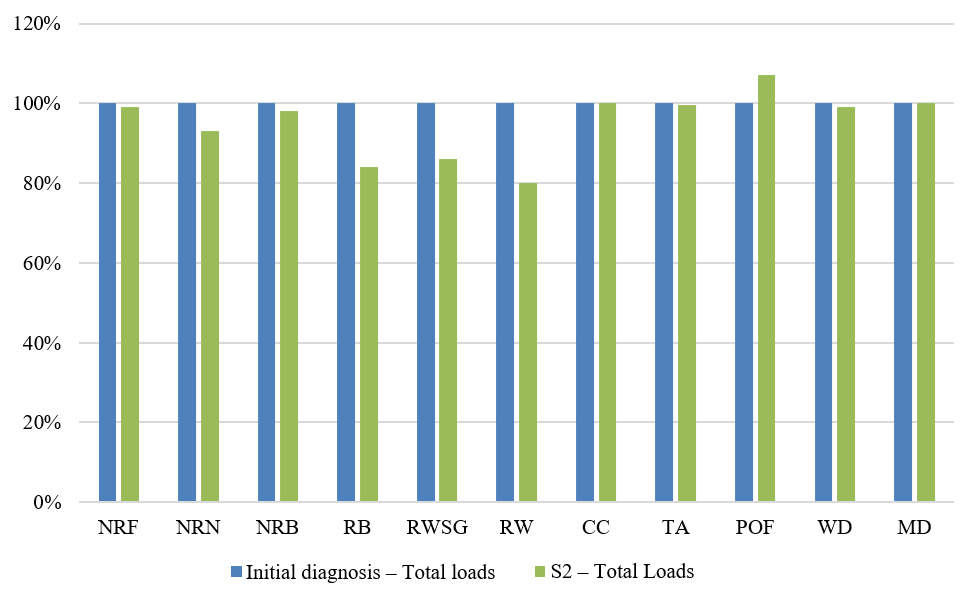

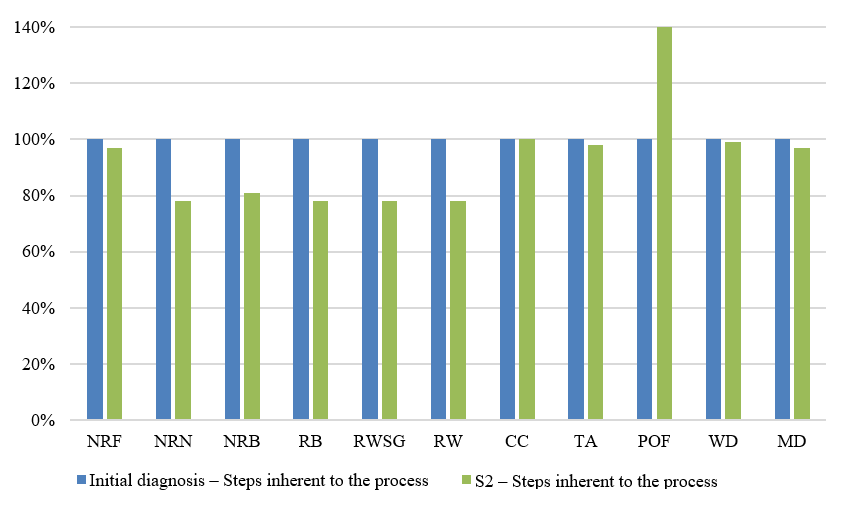

The installation of dry coke quenching (S2) has also not brought any relevant systemic environmental benefits to the Brazilian steel production (Figure 5). However, favourable changes occurred in energy terms for NRN, RB, RWSG and RW. On the other hand, an increase POF contributions was verified. The study was also reworked to verify only the CDQ effect on the inherent stages of the process. This new perspective resulted in NRN (22%), NBR (19%), RB (22%), RWSG (22%) and RW (22%) decreases, with the even greater increase in POF (140%), (Figure 6).

Comparison of the environmental profiles of liquid steel production for the Initial Diagnosis vs S2 - Total loads

As in S1, the use of alternative energy reduces the participation of the Brazilian grid in the process, compared to the initial diagnosis, resulting in a 36% lower consumption. With this reduction, changes can be noted in the energy profile of the system by impact category, where electricity production and transport now comprise a 13% share of NRF, 50% of NRN, 42% of NRB and around 52% of RB, RWSW and RW.

Comparison of the environmental profiles of liquid steel production for Initial Diagnosis vs S2 - Steps inherent to the process

The change proposed by S2 reduce the PED of operations inherent to the process by 14%, with a value of 1.38 MJ/kg. The gains obtained in terms of renewable sources (RB, RWSG and RW) are of 23%, followed by NRN, NRB and NRF impacts, which depletions were of 22%, 19% and 6.6%, respectively. Although NRF had reduced, it continues to contribute with 58% of total PED. Natural gas production and transport account for 73% of this contribution, of which 58 % comes from the extraction of natural gas off the coast of Rio de Janeiro and the remainder from the exploitation of the fossil resource in Bolivia. In addition, around 35% of S2-related PED is concentrated in RW, specifically for hydropower generation.

The CDQ also reduced the CC impacts of the baseline scenario by 1.76 gCO2eq/kg steel. CO2 contributes almost entirely to the category (96%), followed, albeit by far, by N2O (4.0%). The depletion is also linked to the burning of fossil fuels for thermoelectric generation of the Brazilian grid, which emits respectively 11.6 g CO2 and 630 μg N2O/kg steel.

The comparison of the S2 result with that obtained by the initial diagnosis indicated a reduction of 2.9% in TA impacts. Here again, electricity generation has an important share of contribution (10%) driven by SOx and NOx emissions from the combustion of heavy oil, coal, bagasse and natural gas. In the manufacture of steel, losses of SOx also predominate due to the burning of fuels.

NOx emissions account for 53% of total POF impacts. They are followed by releases of CO (35%) and NMVOC (7.6%). The increase in impact caused by S2 compared to the initial diagnosis is due to an intensification of nine times in the CO emissions provided by the CDQ on the steps inherent to steel processing, due to the installation of the gas firing and relief system that is associated with the technology. The gas drained into the atmosphere can contain between 14 and 28% of CO.

The expectation of a significant decrease in process water consumption as a result of the adoption of the CDQ has not been confirmed. If, on the one hand, the exemption of water use for the quenching of coke implied a reduction in WD's impacts, on the other hand, the need for water replacement due to boiler purges, and evaporation in the cooling tower installed due to the CDQ technology ended up cushioning that effect. Also in this case, there was no significant influence of S2 on MD impacts for the inherent steps of the process.

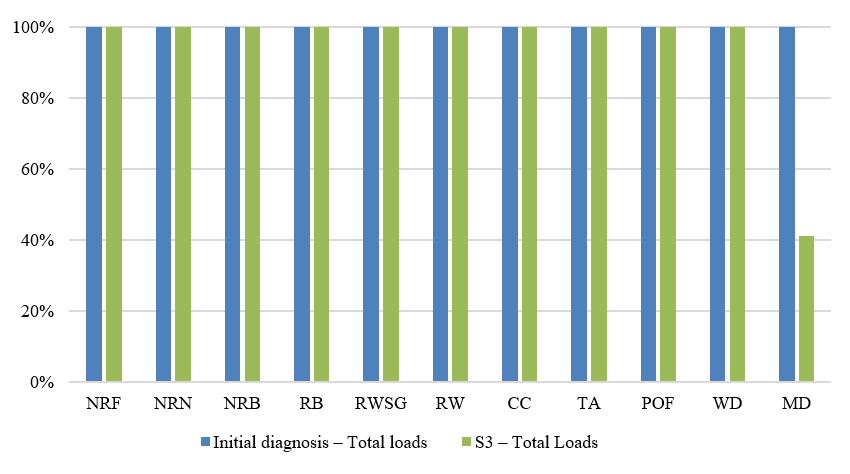

In the original process condition, the manganese ore is supplied by three delivering, with 98% of demand being met by the suppliers A and B. Those raw material come from the Southeast region of Brazil, and are quite similar in terms of composition. Its supplying logistics predisposes a displacement of 860 km by road and rail. The situation explored in S3 consists in attending the process only with Mn ore from the supplier C, which comes from the Northern region of the country and supplies the steel mill complex via maritime modal (3940 km). Despite the distance between origin and destination, this ore has three times less silica (SiO2), about 4.5 times more Mn and nearly 3.8 times less Fe than those distributed by A and B. After applying LCA to this case, minor changes in environmental impacts were noted (Figure 7). The exception occurred for MD, whose result proved to be 59% less than that recorded for the initial diagnosis. For this scenario no discretized analysis was carried out for the loads inherent to the manufacture of the steel itself, given that the change proposed herein reverts exclusively to external stages to this process. The PEDs for the initial diagnosis and S3 are similar, with only a slight reduction in the total energy consumption of the alternative (160 kJ/kg steel) resulting from the accumulation of successive individual decreases in the various impact categories.

The PED for S3 focuses on the extraction and transport of carbon and ferrous materials and the electricity generation. The operations linked to the carbonaceous materials (i.e. coals minerals, CVP and anthracite) demand together 15.8 MJ/kg steel of primary energy.

The share of NRF subcategory remains at 94% of total PED (17.1 MJ/kg steel) as in the initial diagnosis. In terms of contribution by process stages, about 92% are provided by the processing of carbonaceous materials and of this total, 63% comes from actions on coal, 31% are due CVP and the remainder by the anthracite. The life cycle of Mn ore (i.e. the extraction and transportation steps) corresponds to a total energy consumption of (only) 5.30 kJ/kg steel, which projects a relative contribution of 0.03% of the system's primary energy demand for such conditions.

Comparison of the environmental profiles of liquid steel production Initial diagnosis vs. S3 - Total loads

As for the MD category, an increase in Fe consumption (30 kg/kg steel) was verified compared to the initial diagnosis, as well as a reduction in the use of Mn (23 g/kg). When associated, such effects led to an impact reduction of 1.14 kg Feeq/kg steel. Considering the same Fe and Mn levels as in the minerals used for the initial diagnosis assessment (47 and 61%), and the consumption described in Figure 2, the demands for these mineral for S3 were of 470 g Fe and 4.20 g Mn/kg steel. Bearing in mind that their impact factors for the category are of IFFe = 1.00 and IFMn = 76.6, respectively, the participation of each of these metals for the said effect is 470 and 322 g Feeq/kg steel.

In addition to the cases evaluated in this study, other impact foci can be addressed with the purpose of improving the environmental performance of Brazil's steel industry. This occurs for example with the consumption of non-renewable solid fuels, whose high demand [37] leads to a significant depletion of natural resources and emissions of GHGs and particulate matter into the atmosphere. The change of such inputs by less aggressive alternatives has become a concrete possibility to mitigate those effects. According to Cavalcanti [37], mineral coal and oil derivatives can be replaced by hydrogen in the conversion of iron ore into pig iron, which will then be re-fused in electric arc furnaces.

While both the H2 synthesis and the arc furnace operation are energy-intensive, a situation that could be offset by a renewable grid like Brazil's, significant reductions in air releases of Greenhouse Gases and Acid Rain could be achieved by this arrangement. After further exploration, Bhaskar et al. [37] developed a mass and energy flow model based on an open-source software (Python) to explore the feasibility of using hydrogen direct reduction of iron ore coupled with electric arc furnace for carbon-free steel production. Modelling results showed that an integration of such technologies could reduce specific emissions from steel production in Europe by more than 35%. The use of renewable fuels such as charcoal, other biomass or biogas can also decarbonise the steel industry and thereby reduce GHG emissions and increase its energy efficiency [50].

A frequent alternative for reducing GHG emissions in steelmaking is to replace oil-based fuels with natural gas or liquefied natural gas. Ahlström et al. [51] reiterate that the action reduces but does not eliminate the release of precursors of Global Warming. For these authors, global emission levels close to zero will only be achieved when fuels used to transport raw materials and process inputs are replaced by substitutes of renewable origin such as liquefied biomethane. In this regard, Bosch et al. [52] investigated the synthesis of biogas from forest residues by dual-fluid bed gasification, finding that the process can achieve high conversion rates at competitive production costs if conducted under appropriate conditions. Alamia et al. [53] maintain that in addition to using robust technology, the availability of biogas as a vehicle fuel will only be possible if the existing fuel distribution and storage infrastructure is harnessed.

Finally, intra-process measures can also help reduce the thermal demand of the steel production cycle [54]. In this context, it is worth noting: (i) the control of coal humidity, and the installation of heat recovery furnaces in the coke plant; (ii) the deepening of the bed, the reduction of air leakage and the recovery of residual heat in sintering; (iii) the optimization of combustion systems, the increase of natural gas and pulverized coal injections for the rationalization of coke consumption, and the use of gases for the pre-heating of air in the blast furnaces; and, (iv) the use of scrap in the cold load of steel production, and the recirculation of steelworks gas. According to Zperansa et al., these measures can reduce the thermal requirements of steelmaking by between 5.0 and 35% if implemented individually or collectively.

The analyses carried out herein indicate that the main sources of environmental impacts associated with the production of liquid steel result from the consumption of diesel oil in the process itself, from coal mining activities and, more significantly, from raw material and input transportation activities.

Diesel consumption was the majority in terms of PED, in the form of NRF depletion. In addition, it was also responsible for the most significant environmental impacts in terms of CC, TA and POF. Coal mining was even more eclectic regarding participation in the evaluated impact profiles when presenting contributions in terms of CC, TA and EUT. Finally, transport actions also play a role in this process, partly motivated by the internal unavailability of process inputs (in the case of mineral coal itself, as well as anthracite) and the distancing of the manufacturing unit considered for the purpose of this analysis of centres supplying raw materials, for example, iron ore and process additives (manganese, limestone, and dolomite).

In this context, the LCA technique met the expected objectives and a consistent and representative diagnosis of the environmental performance of steel production was generated for the conditions in which it occurs in the country. While the conduct of assuming premises for the elaboration of an LCA makes the model deterministic, on the other hand, such a strategy proves to be an efficient strategy to minimise the effects of various uncertainties (i.e. of data, and those derived from methodological decisions). These considerations reflect the general case of steel processing for the Brazilian condition and, therefore, the diagnosis generated from them, as well as the ones that may result from them, will also serve to guide situations with similar characteristics in terms of processing technology and/or methodological approach. In addition, it should be noted that the formulation of this profile provided the means for this project to be carried out, by identifying potential focuses for the application of improvement actions.

From this, three solution scenarios were defined, specified and sized. S1, which consisted of reusing the gas from the steelmaking process, allowed for the identification of relevant improvements in environmental performance in terms of Primary Energy Demand (PED) in all analyzed impact categories (NRF, NRN, NRB, RB, RWSG and RW). On the other hand, only slight variations were observed in terms of impacts such as emissions. The energy generation and transportation stage are noteworthy concerning the intensity of the impacts presented herein, being responsible for the magnitude of the improvement. The presented proposal reduced the electricity dependence of the national grid and, therefore, impacts related to this stage of the process were reduced in the presented categories.

S2 included the implantation of technology for raw coke dry quenching (CDQ). This scenario presented an environmental profile very similar to that described for S1, since it also reduces the electricity dependence of the national grid. Improvements were also verified for the impact categories NRF, NRN, NRB, RB, RWSG and RW. Low impact was verified in terms of emissions, in the forms of CC, TA, WD and MD. However, environmental performance worsening in terms of POF was detected, since S2 showed an increase in carbon monoxide (CO) emissions, due to the relief systems associated with the CDQ. S3, which dealt with the change in the manganese ore supplier, diverged from S1 and S2, with significant improvement only in the MD category, a result that would be expected beforehand. For the other effects, little impact fluctuation observed.

The LCA fulfilled the objectives expected from a diagnostic technique, to identify potential foci for generating impacts and verify effects resulting from potential actions to improve performance. Although the values quantified both in terms of PED, and due to the emission to the environment may seem discrete, one must take into account the significant volume of steel produced in Brazil every year. In order for actions to improve the environmental performance of this production cycle to be observed at a systemic level, the participation of the environmental variable in managerial decision-making processes that occur in the steel sector is essential, as is already the case in other sectors.

This study was funded in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brazil (CAPES) Finance Code 001.

|

|

|

|

As |

Arsenic |

|

ABNT |

Brazilian Association of Technical Standards |

|

BFG |

Blast Furnace Gas |

|

BOF |

Converter |

|

C |

Carbon |

|

CC |

Climate Change |

|

CCS |

Carbon Capture and Storage |

|

CQD |

Coke Dry Quenching |

|

CED |

Cumulative Energy Demand |

|

CH4 |

Methane |

|

CO |

Carbon Monoxide |

|

CO2 |

Carbon Dioxide |

|

CO2eq |

Carbon Dioxide Equivalent |

|

CVP |

Green Petroleum Coke |

|

EAF |

Electric Arc Furnace |

|

EUT |

Eutrophication |

|

Fe |

Iron |

|

GHG |

Greenhouse Gases |

|

HT |

Human Toxicity |

|

IaBR |

Institute Steel Brazil |

|

IF |

Impact Factor |

|

NTI/GDP |

Normalized Total Impacts/Gross Domestic Product |

|

ISO |

International Organization for Standardization |

|

LCA |

Life Cycle Assessment |

|

LCI |

Life Cycle Inventory |

|

LCIA |

Life Cycle Impact Assessment |

|

LDG |

Steelmaking Gas (Linz-Donawitz Converter Gas) |

|

Mn |

Manganese |

|

MD |

Metal Depletion |

|

NMVOC |

Volatile Organic Compounds Other Than Methane |

|

NOx |

Nitrogen Oxides |

|

NRB |

Non-Renewable Biomass |

|

NRF |

Non-Renewable Fossils |

|

NRN |

Non-Renewable Nuclear |

|

OHF |

Open Hearth Oven |

|

O2 |

Oxygen |

|

P |

Phosphorus |

|

PED |

Primary Energy Demand |

|

POF |

Photochemical Oxidant Formation |

|

PO43- |

Phosphate |

|

RB |

Renewable Biomass |

|

RW |

Renewable Water |

|

RWSG |

Natural Effects Energy (Wind, Sun and Geothermal) |

|

Se |

Selenium |

|

SiO2 |

Silica |

|

SOx |

Sulphur Oxide |

|

TA |

Terrestrial Acidification |

|

WD |

Water Depletion |

|

WF |

Water Footprint |

- , Corredores Logísticos Estratégicos: Complexo de Minério de Ferro, 2018

- , Anuário Mineral Brasileiro: Principais Substâncias Metálicas, 2018

- ,

Estatística Preliminar ,Instituto Aço Brasil , Vol. 52 ,pp 1-11 , 2019 - , Proposição de Melhorias do Desempenho Ambiental do Processo de Produção do Aço Líquido Proposição de Melhorias do Desempenho Ambiental do Processo de Produção do Aço Líquido, 2016

- ,

Development of secondary-fuel injection technology for energy reduction in the iron ore sintering process ,ISIJ International , Vol. 51 (6),pp 913-921 , 2011, https://doi.org/10.2355/isijinternational.51.913 - ,

Effects of waste recovery on carbon footprint: A case study of the Gulf of Bothnia steel and zinc industries ,Journal of Cleaner Production , Vol. 19 (16),pp 1857-1864 , 2011, https://doi.org/10.1016/j.jclepro.2011.04.014 - ,

Environmentally responsible policy of wastes in steel industry ,Metalurgija , Vol. 59 (1),pp 77-80 , 2020 - ,

Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in europe ,Metals , Vol. 10 (3), 2020, https://doi.org/10.3390/met10030345 - ,

Reducing the greenhouse gas footprint of primary metal production: Where should the focus be? ,Minerals Engineering , Vol. 24 (14),pp 1563-1570 , 2011, https://doi.org/10.1016/j.mineng.2011.08.007 - , World steel in figures 2019, 2019

- ,

Modeling Sintering Process of Iron Ore ,Sintering - Methods and Products , 2012, https://doi.org/10.5772/33613 - Aço: Processo de Fabricação. Processos de Aglomeração de Minérios: Sinterização e Pelotização., 2015, http://www.infomet.com.br, [Accessed: 20.10.2019]

- ,

Thermal implications of phase transformations during induration of iron ore pellets produced from hematite ,ISIJ International , Vol. 45 (11),pp 1561-1566 , 2005, https://doi.org/10.2355/isijinternational.45.1561 - , Processo de Fabricação do Coque, 2013

- , The State–of-the-Art Clean Technologies (SOACT) for Steelmaking Handbook (2nd Edition)., 2010

- , Redução de Minério de Ferro: Altos Fornos, 2013

- , , Modern Blast Furnace Ironmaking, an introduction, 2009

- ,

The potential for improvements in energy efficiency and CO2 emissions in the EU27 iron and steel industry under different payback periods ,Journal of Cleaner Production , Vol. 52 ,pp 71-83 , 2013, https://doi.org/10.1016/j.jclepro.2013.02.028 - ,

The steel industry, abiotic resource depletion and life cycle assessment: A real or perceived issue? ,Journal of Cleaner Production , Vol. 19 (1),pp 78-90 , 2011, https://doi.org/10.1016/j.jclepro.2010.08.020 - , Sustainable steel: at the core of a green economy, 2012

- ,

Study of CO2 emissions in China’s iron and steel industry based on economic input–output life cycle assessment ,Natural Hazards , Vol. 81 (2),pp 957-970 , 2016, https://doi.org/10.1007/s11069-015-2114-y - ,

Comparison of greenhouse gas emission accounting methods for steel production in China ,Journal of Cleaner Production , Vol. 83 ,pp 165-172 , 2014, https://doi.org/10.1016/j.jclepro.2014.07.016 - ,

An analysis of energy-related greenhouse gas emissions in the Chinese iron and steel industry ,Energy Policy , Vol. 56 ,pp 352-361 , 2013, https://doi.org/10.1016/j.enpol.2012.12.068 - ,

An analysis of energy-related greenhouse gas emissions in the Chinese iron and steel industry ,Energy Policy , Vol. 56 ,pp 352-361 , 2013, https://doi.org/10.1016/j.enpol.2012.12.068 - NBR ISO 14044: Gestão Ambiental - Avaliação do Ciclo de Vida - Requisitos e orientações , 2009

- , Implementation of Life Cycle Impact Assessment Methods. ecoinvent report No. 3, v2.0. Swiss Centre for Life Cycle Inventories., 2007

- , Balanço Energético Nacional 2019: Relatório síntese, ano base 2018., 2019

- , Estudo para o uso de matérias-primas nacionais em misturas de carvões para obtenção de coque com características requeridas em altos-fornos de alta produtividade, 2007

- Balanço Energético Nacional 2019 , 2019

- ,

Occurrence of phosphorus minerals in Australian coal seams ,International Journal of Coal Geology , Vol. 30 (3),pp 185-210 , 1996, https://doi.org/10.1016/0166-5162(95)00055-0 - Climate change and the measurement of greenhouse gases from coal mining environments: a strategic response , 2003

- ,

European Residual Mixes 2017 Association of Issuing Bodies ,The International Journal of Life Cycle Assessment , Vol. 3 ,pp 1236-1254 , 2016, https://doi.org/10.1007/s11367-013-0665-2 - , , Água, Indústria e Sustentabilidade, 2012

- ,

Relatório de Sustentabilidade da indústria brasileira do aço ,pp 84 , 2018 - , Water Use in Industries of the Future: Steel Industry, 2003

- ,

Minimização do Consumo de Água e da Geração de Efluentes Líquidos em Siderurgia ,pp 173 , 2012 - , , Description of the ReCiPe methodology for life assessment impact assessment., 2013